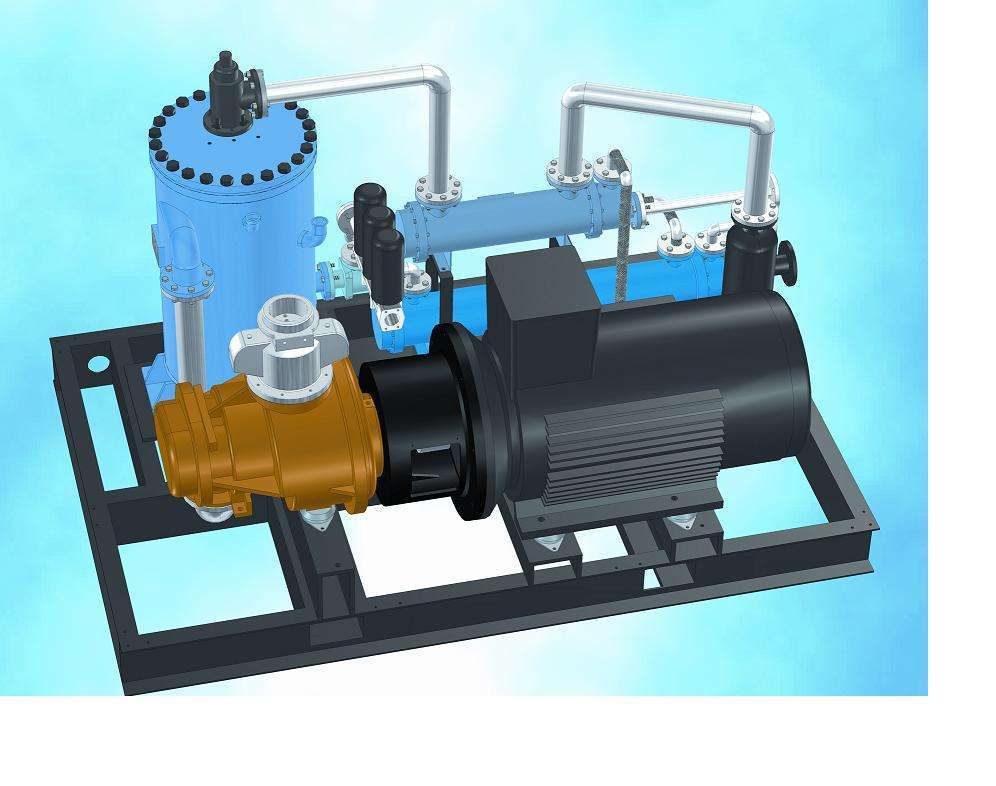

The working principle of a screw air compressor is that the Yin and Yang rotor of a pair of parallel meshing rotates in the cylinder so that the air between the rotor grooves constantly produces periodic volume changes. The atmosphere is transported from the suction side to the output side along the rotor axis, realizing the whole process of suction, compression, and exhaust of the screw air compressor.

Traditional air compressors use star triangle buck start. However, the current can still reach 2~3 times the rated current when the power frequency starts, and the impact is significant, affecting the power grid’s stability. And most of the air compressor is continuous operation because the motor itself of the general air compressor can not achieve speed reduction according to the change of pressure-demand, so that the output power of the engine matches the actual pressure-demand on-site, resulting in empty operation when the gas consumption is low, resulting in a massive waste of electricity. According to statistics, air compressors account for almost 15% of large industrial equipment power consumption (fans, pumps, boilers, etc.). The energy-saving transformation of air compressors is of great significance.

The operation of a screw air compressor is mainly composed of procurement cost, maintenance cost, and energy cost. Energy costs account for about two-thirds of total operating expenses. Thus, by reducing energy costs by 30%, coupled with frequency conversion starting after the impact on the equipment is reduced, maintenance and repair also follow the reduction, so it will significantly reduce operating costs. The frequency conversion control system has accurate pressure control capability. By matching the air pressure output of the air compressor with the air volume required by the user’s air system, the system pressure of the pipe network can be kept constant, and the air supply quality can be effectively improved. The frequency converter has the function of soft start, which can reduce the impact on the compressor and mechanical parts when starting, enhance the system’s reliability, and prolong the compressor’s service life. At the same time, reduce the impact of air compressor startup on the power grid.

As screw air compressor in the industry, mining industry, medical industry, and even agriculture have an increasingly wide range of USES, especially in the field of industrial air compressor power consumption problematic: first, the vast majority of air compressor, motor-driven way after the filter, air into the compressor to compress air, compressed air after separation of oil and gas output. As long as the air compressor is working and the motor is running at a rated speed, the output air flow rate of the air compressor is adjusted by the size of the inlet valve opening. It is running at rated speed even when unloading produces no functional loss. Therefore, it is necessary to take various measures to adjust the compressor’s output so that the motor always works at the appropriate load and saves energy.